The article explores the subject of ladder safety, with a special emphasis on the EN131 ladder safety standards—a critical guideline for ladder design and use.

Introduction: The Crucial Importance of Ladder Safety

Before we jump to the specifics of the EN131 standards, let's discuss why ladder safety is a topic of such significance. Ladder-related accidents are more common than we might think, often leading to severe consequences for individuals and businesses. Understanding and complying with safety standards can make a world of difference.

Introducing the EN131 Ladder Safety Standards

The EN131 standards, established by the European Committee for Standardization (CEN), are comprehensive guidelines that pertain to portable steps and ladders. These standards encompass ladders made from various materials, including metal and FRP (Fiberglass) The primary objective of EN131 is to establish minimum safety requirements for these essential equipment.

The EN131 Standard & 7 Parts For Specific Purpose:

Part 1, the standard establishes essential terminology, defines ladder types, and outlines functional sizes, providing a foundational understanding of the subject.

Part 2 takes a deeper dive into the requirements, testing procedures, and marking criteria, ensuring that ladders meet stringent safety standards.

Part 3 focuses on marking and user instructions, emphasizing the importance of clear guidance for safe ladder usage. For those dealing with single or multiple hinge-joint ladders,

Part 4 provides specialized guidelines.

Part 6 addresses telescopic ladders, offering specific considerations for this type of ladder. Finally,

Part 7 deals with mobile ladders equipped with platforms, emphasizing safety measures for ladders with added mobility and functionality.

Together, these seven parts of the EN131 Standard create a comprehensive framework that promotes ladder safety and reliability across various ladder types and designs.

Understanding the Need for Ladder Safety

The importance of adhering to safety standards cannot be overstated. The European Commission recognized the need for enhanced ladder safety and updated the EN131 standards. This update includes additional requirements for ladder stability, slip resistance, durability, and strength in the position of use—key aspects to avoid ladder-related accidents.Major Tests Covered by EN131 Standard

To ensure compliance with EN131 standards, ladders undergo rigorous testing. Here are the major tests that determine whether a ladder meets the required safety criteria:

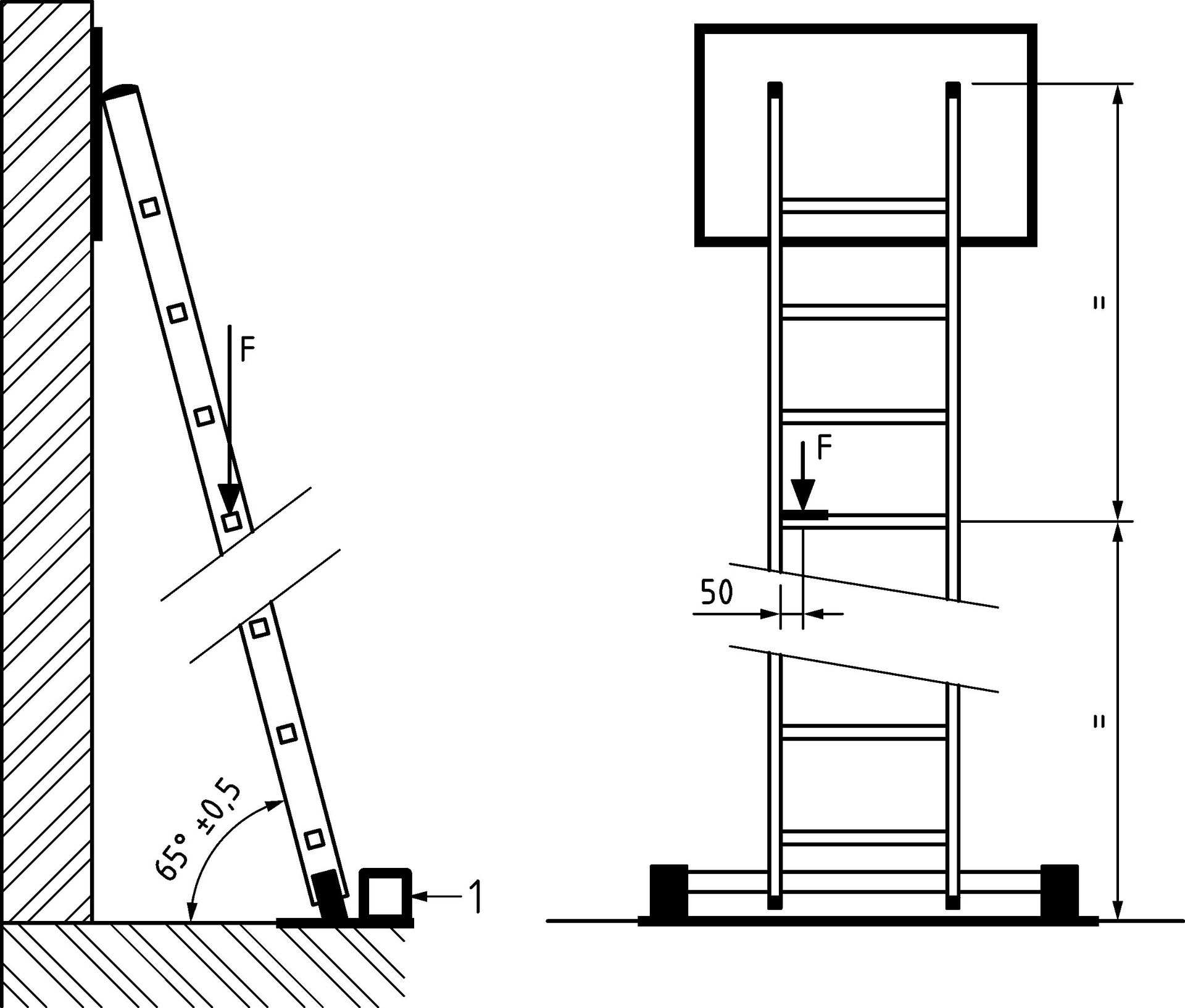

Leaning Ladder Test (The Base Slip Test): Assessing the slip resistance of ladder feet during use.

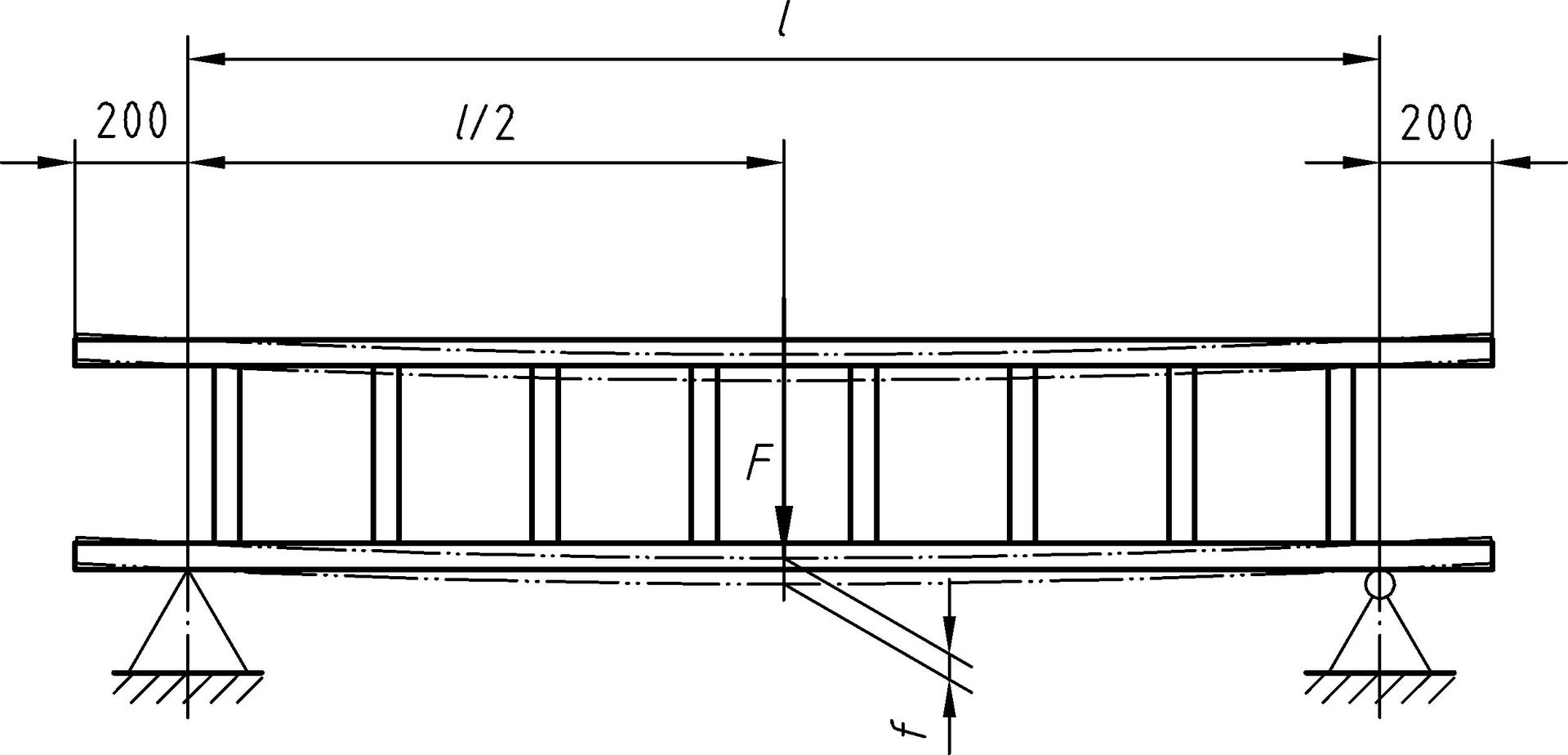

Lateral Deflection Test: Measuring the lateral bend of the ladder when laid on its side.

Bend Test: Evaluating the bending behavior of the ladder on a test rig.

Strength Test: Testing the ladder's strength in its intended position of use.

Torsion Test: Examining the twist movement of the ladder on a test rig.

Durability Test: Ensuring the ladder's long-term durability.

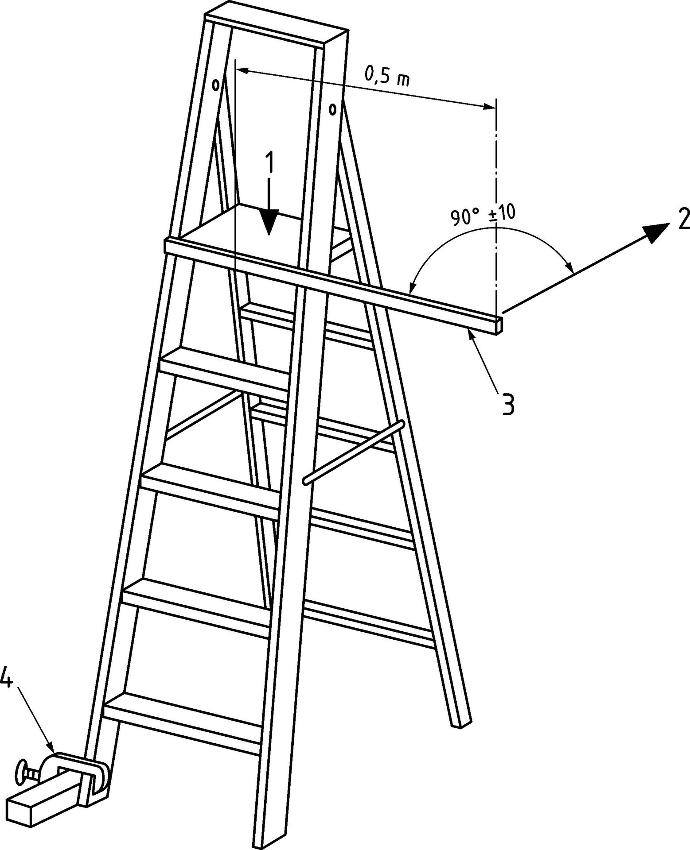

Opening Restraints and Hinge Test: Assessing the durability of ladder opening restraints and hinges.

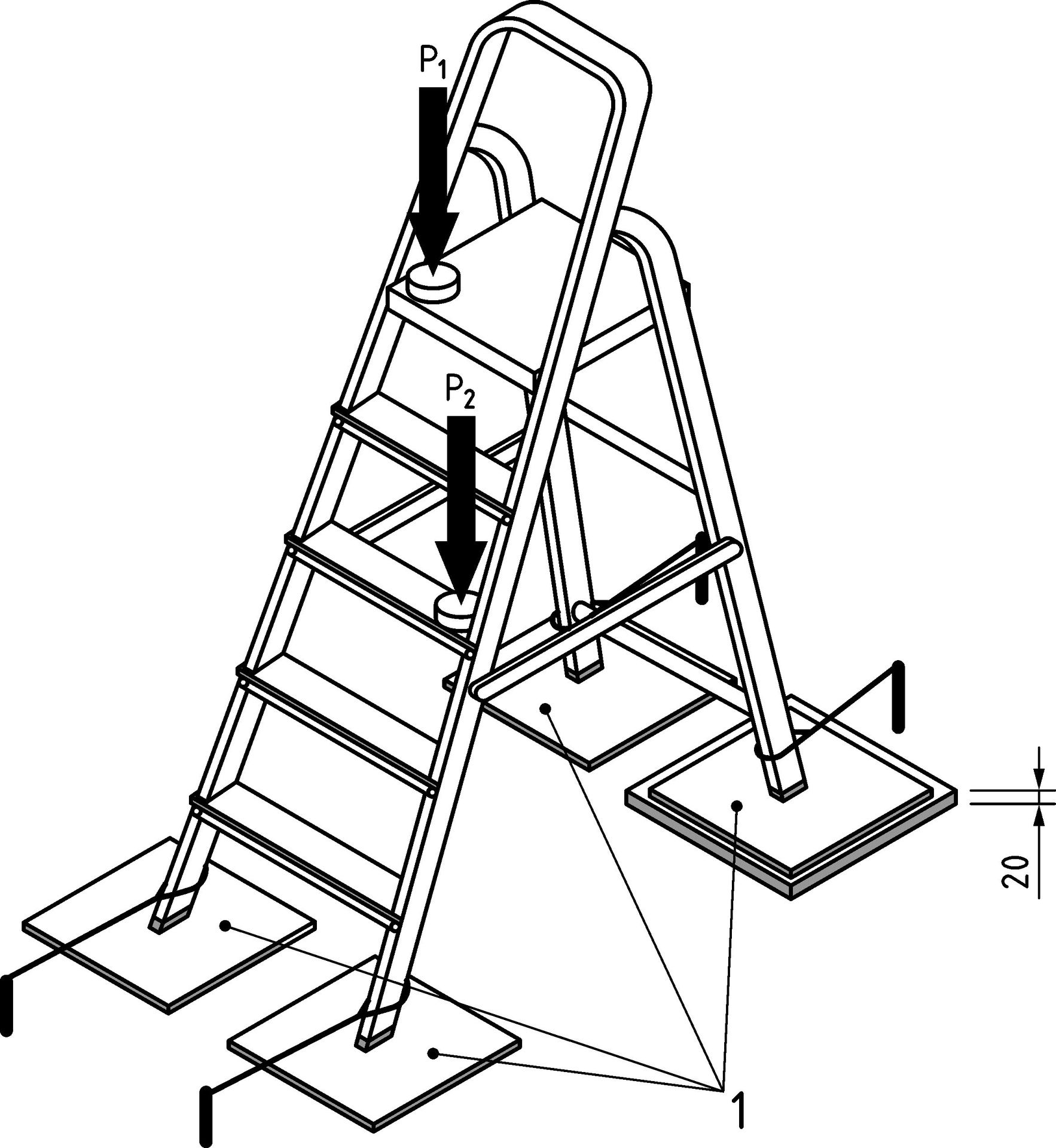

Stiffness & Stability Test: Confirming ladder stability on various surfaces and assessing its stiffness.

Key Changes in the New EN131 Standards

The new EN131 standards represent a significant leap forward in ladder safety. Some notable changes include testing ladders in their position of use and clarifying testing methodologies to ensure consistency across manufacturers and testing facilities. These changes are pivotal in preventing the main causes of ladder-related accidents.

Types of Ladders Covered by EN131

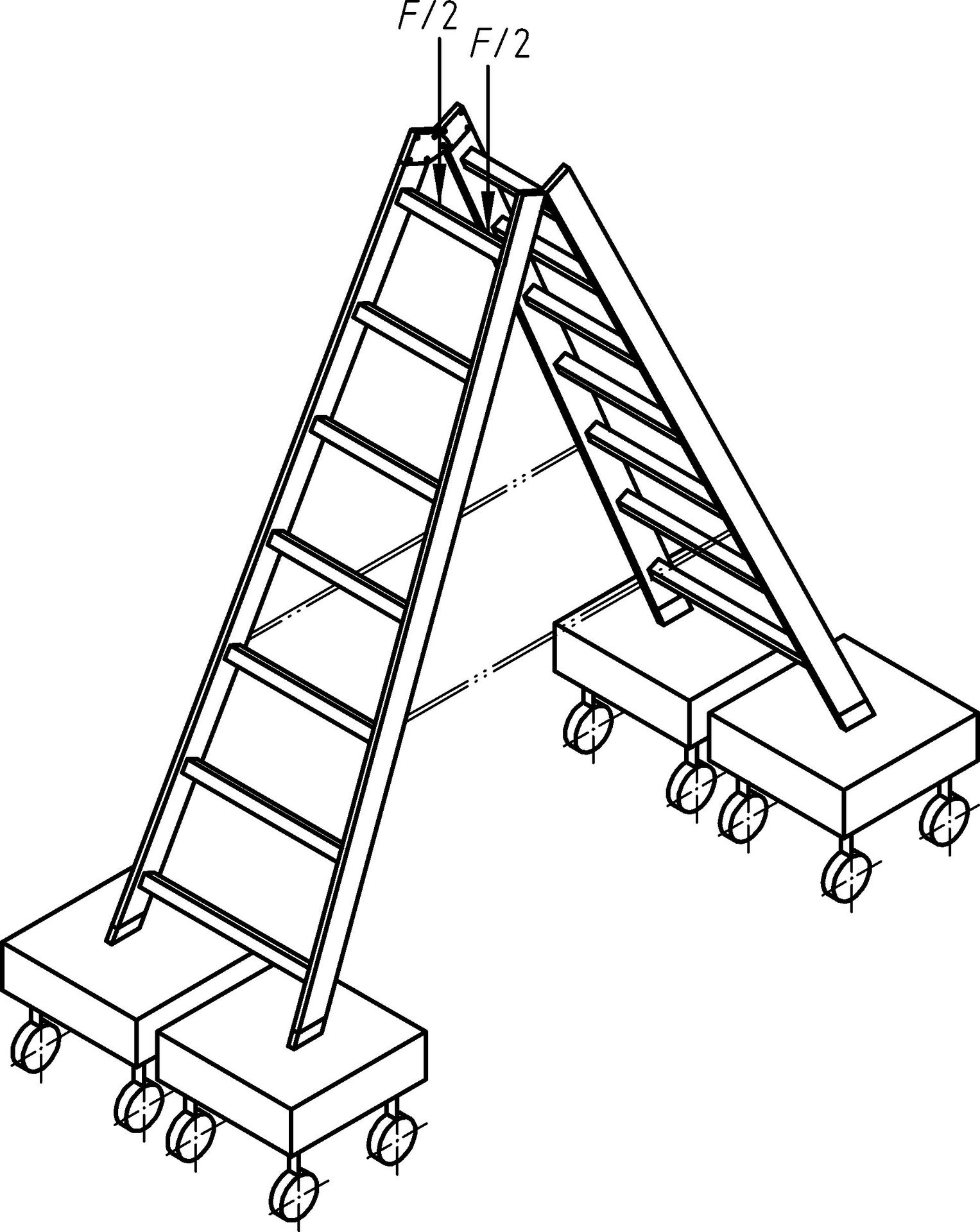

EN131 standards cover a wide range of ladders, including A-type, extension, straight, and platform ladders. Each ladder type is subject to specific safety requirements outlined in the standards.

1. For multiple hinge joint ladders EN 131–4 applies.

2. For telescopic ladders EN 131–6 applies.

3. For mobile ladders with platforms EN 131–7 applies.

4. This standard does not apply to step stools for which EN 14183 applies

Benefits of Adhering to EN131 Standards

Compliance with EN131 standards offers numerous advantages, both for manufacturers and users:

- Manufacturers benefit from improved product quality and safety.

- Users and workers can trust that EN131-compliant ladders are safer to use and maintain.

Contrasting the New EN131 Standards with Older Ones

While many aspects of the standards remain similar, the new EN131 introduces stabilizers for ladders over 3 meters, new slip tests, cycle durability tests, and tests for ladders in the position of use. Additionally, the maximum load rating is standardized at 150kg.

Choosing the Right Ladder:

Selecting the appropriate ladder is paramount. Products must undergo independent testing and certification for compliance with the new EN131 standard to ensure safety and reliability.

Article:

Your Guide to Ladder Safety: Dos and Don'ts You Should Know

What if Products Do Not Comply with EN131?

Industries should prioritize compliance with EN131 standards, as this compliance serves as the foundation for basic safety requirements.

Importance of Regular Ladder Inspections & Maintenance

Regular ladder inspections and maintenance are vital to ensure that ladders remain safe for use over time.

Conclusion

In conclusion, ladder safety is a critical concern for all industries where ladders are used. The EN131 standards represent a significant step forward in enhancing ladder design and safety. By adhering to these standards and understanding their implications, we can create a safer work environment for all.

Why Youngman?

Looking for a ladder to prioritize safety? Then check Youngman Manufacturing's range of EN131-certified ladders. Our products are designed to provide superior protection while ensuring maximum productivity. Trusted by over 10,000 industries. So, do not compromise on safety, choose Youngman Manufacturing for all your scaffold needs. Reach out to us at: sales@youngman.co.in or call: +91-9015964626