Both designs have their advantages. In this article, we aim to understand, as per EN1004 standards, how Integrated Vertical Ladder towers compete with Staircase Scaffold Towers.

Comparison Between Integrated Vertical Ladder & Staircase Towers

One of the standout features of integrated vertical ladder towers lies in their ability to provide easy, quick, and uncomplicated access to various levels. This is achieved through the 3T method, ensuring rapid ascension and descent, ultimately saving valuable time in tower erection.

This quick access contributes significantly to enhanced productivity than staircase scaffold towers on the job site.

Versatility is another key advantage of vertical integral ladders. These towers can be easily customized to accommodate various job heights and tasks, making them adaptable for a wide range of projects.

The material efficiency of vertical ladder scaffold towers is noteworthy, requiring fewer materials compared to alternatives like staircases or external ladders.

This not only streamlines the projects but also minimizes the environmental impact associated with manufacturing and transporting additional components, aligning with a more sustainable and resource-efficient construction approach.

These parameters need to be considered when choosing the tower

Pros of Integrated Vertical Ladder Scaffold Tower

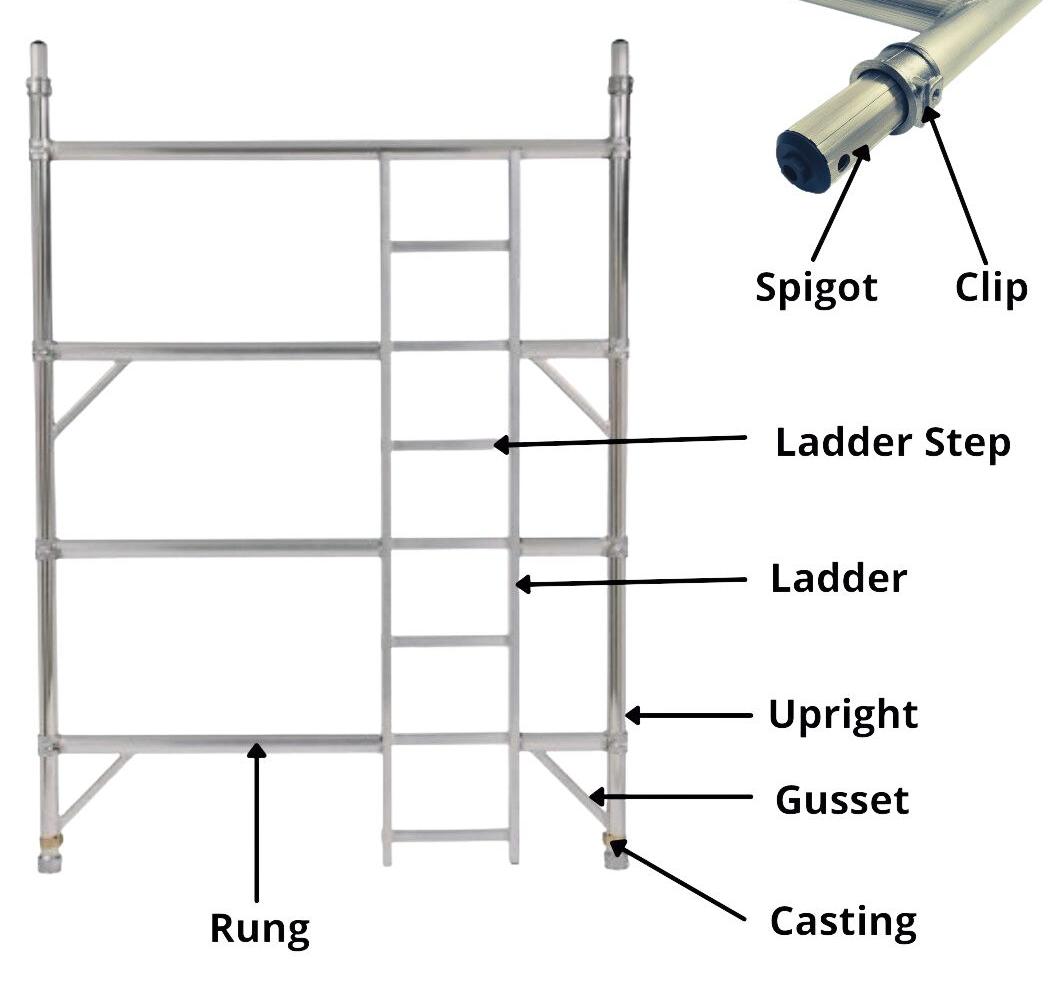

Quick Access (By 3T Method): The ladder's integral design simplifies access to various scaffold levels, employing the 3T Method (Through the Trap Door). It offers swift ascent and descent for workers, significantly boosting productivity and time savings.

This design streamlines the process, allowing quick movement between levels without complexity. This accessibility enhancement enables seamless transitions, ensuring efficiency during tasks.

Versatility: Vertical integral ladders stand out due to their adaptability across different job heights and tasks. Their flexibility allows for effortless customization, making them an ideal choice for a diverse array of projects.

These ladders effortlessly cater to various needs without compromising on safety or efficiency.

Their versatility makes them a reliable option for a wide range of tasks, ensuring convenience and ease of use in any project scenario.

Whether for routine maintenance, construction, or repairs, these ladders remain a practical solution, providing stability and support while simplifying work at different elevations.

Material Efficiency: Vertical ladder scaffold towers typically require fewer materials than other access solutions, such as staircases or external ladders.

This efficiency in material usage minimizes the environmental impact associated with manufacturing and transporting additional components.

It contributes to a more sustainable and resource-efficient construction approach.

Cons of Staircase Towers

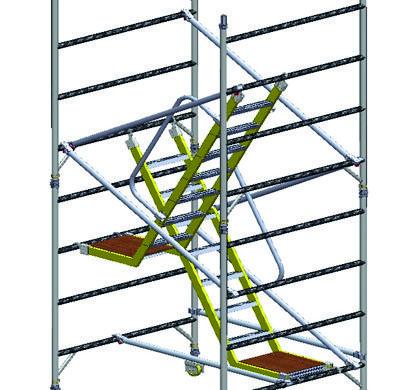

Decreases the Safe Working Load: When utilizing the staircases within a tower, it incrementally elevates this load, thereby impacting the Safe Working Load (SWL) over time.

Consequently, as the dead load increases due to the presence of staircases, the SWL of the tower gradually diminishes.

This factor emphasizes the need for periodic assessment and consideration of load-bearing capacities to ensure continued safety and structural integrity within the building.

Additional Attachment Requirement: Stairway scaffold towers often require supplementary attachments and safety features such as handrails, to meet safety regulations.

This results in added complexity and cost in terms of assembly, maintenance, and compliance.

Increased Tripping and Falling Risk: The presence of stairs can create trip hazards, and users may be more susceptible to falls on stairway scaffold towers.

Stairs are less forgiving than ladders, and even minor obstructions or debris on the stairs can pose safety risks.

Article: Comprehensive Guideline to Minimizing Risks During Work at Height

Height Restrictions: The staircase on scaffold towers comes with some unique height adjustments that restrict it to fit different tower heights.

As per EN1004, the length of the staircase cannot be less than 1.75 meters and should be between the angles of 35 to 55 degrees which impacts the overall height flexibility.

Article: Guide to Scaffolding (Mobile Access Tower) Safety: Dos and Don'ts You Should Know

Special thanks to The Safety First for their invaluable assistance in crafting this article. Their expertise and dedication to promoting safety in the industry have been instrumental in providing valuable insights and guidelines for our readers.

Why Youngman Ladderspan Tower?

Looking for a scaffold tower to prioritize safety? Then check Youngman Manufacturing's Ladderspan Tower. Our products are designed to provide superior protection while ensuring maximum productivity.

Trusted by over 10,000 industries. So, do not compromise on safety, choose Youngman Manufacturing for all your scaffold needs. Reach out to us at: sales@youngman.co.in or call: +91-9015964626