Importance of Ladder Safety

Why do so many people get hurt on ladders every year? It's a big question, but the answer is simple: ladder safety matters a lot. Ladders might seem like basic tools, but they can be dangerous if not used correctly. Every year, lots of folks end up getting hurt, and sometimes even worse, because of ladder accidents.

Falls and ladder failures are serious, and that's why understanding ladder safety is super important. Knowing how to use ladders safely can make a big difference in keeping everyone safe, especially when working with tall ladders or extension ladders.

Overview of Extension Ladders

Extension ladders are those handy tools/work-at-height equipment we use to reach high places safely. They're designed for exactly that: giving us access to places up extra high without any hassle.

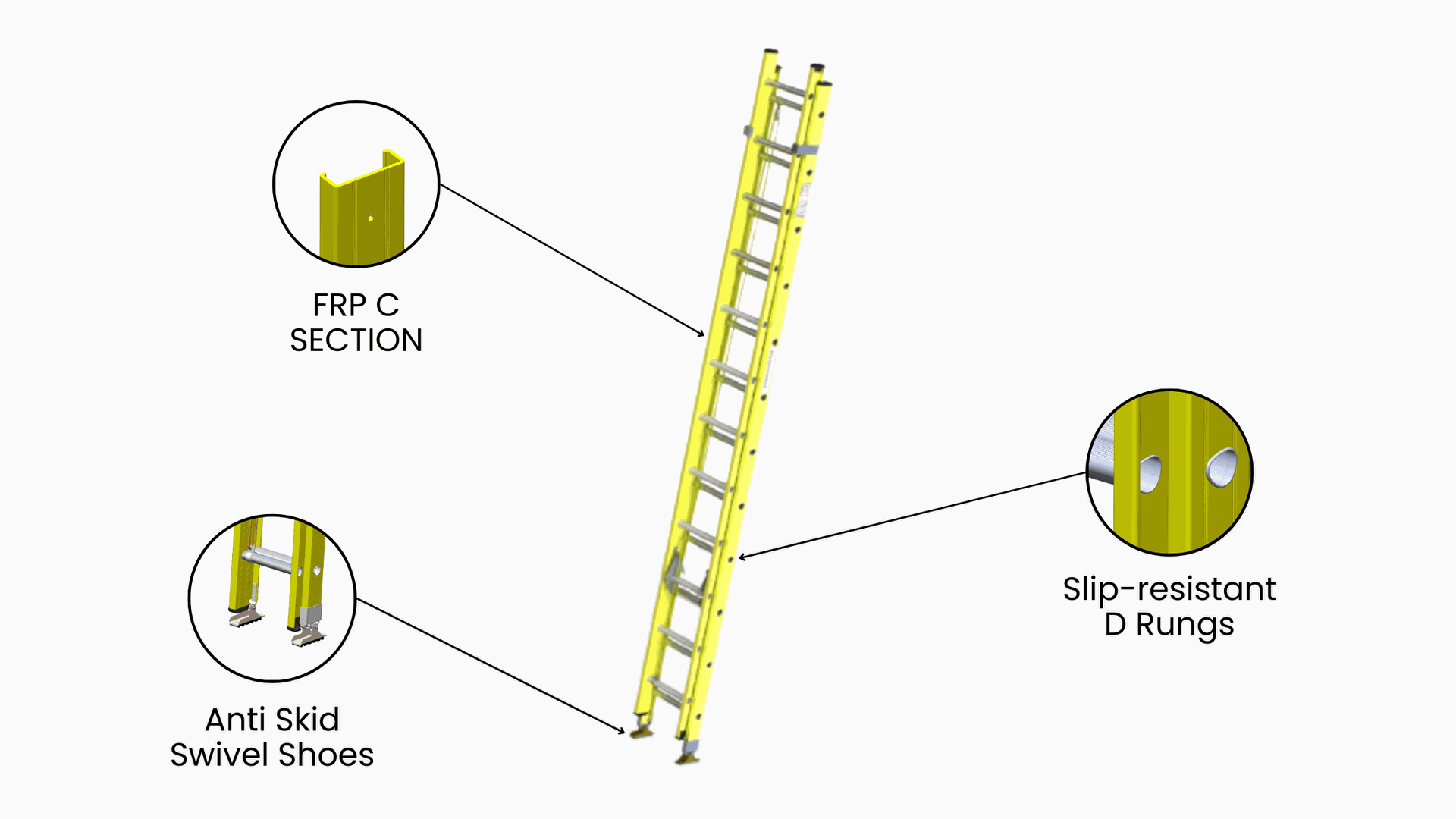

These ladders have a few key parts that make them work well and keep us safe. They've got anti-skid rubber shoes to keep them steady on all sorts of surfaces. Plus, there's a pulley system that helps extend and retract them smoothly. And don't forget about the D-shaped rungs and slip-resistant steps for good grip and stability. With a nylon rope for controlled operation, extension ladders are all about safety and ease of use.

Choosing the Right Extension Ladder For the Job

Height and Reach Requirements: It's essential to ensure that the ladder's height matches the task, eliminating the need to stand on the top rungs which can be unsafe. Assess the maximum height you need to reach and choose a ladder that comfortably matches that requirement. It not only ensures efficiency but also minimizes the risk of accidents due to overreaching. When considering extension ladder types, keep in mind the specific requirements of your task.

Material Options: When selecting a ladder, consider the environment in which it will be used. For instance, if there are electrical wires nearby, it's advisable to go for non-conductive materials like fiberglass or FRP extension ladders. Aluminum ladders are lightweight and durable but conduct electricity, making them unsuitable for certain work environments. Fiberglass, on the other hand, provides excellent insulation against electrical hazards.

Article: FRP Ladder and Its Top 5 Work at Height Safety Benefits

Weight Capacity and Load Limits: Always verify the ladder's weight capacity to ensure it can safely support your weight along with any tools or materials you'll be carrying. Exceeding the weight limit poses a significant safety risk, potentially leading to structural failure or accidents. Be meticulous in assessing the combined weight of yourself, equipment, and materials before selecting a ladder.

Safety Certification: Look for ladders that meet recognized safety standards such as EN131 for both aluminum and fiberglass (FRP) ladders, and ERDA certification specifically for fiberglass ladders. EN131 certification guarantees that the ladder meets stringent criteria for strength, stability, and performance, ensuring reliability in various working conditions. ERDA certification is crucial for ladders intended for use in electrical environments, signifying their suitability and safety in such settings.

Article: Which Standard to be Followed for Ladder Safety

Anchor Points and Securing Methods: Securely anchoring the ladder is imperative to prevent slips, falls, or tipping. Ensure the ladder's feet are firmly planted on stable ground, and if necessary, use additional securing methods such as straps or braces to stabilize the ladder further. Proper anchoring enhances stability, reducing the risk of accidents during use.

Note: In high-risk situations or when working at considerable heights, consider utilizing a safety harness with the extension ladder. That provides an additional layer of protection, minimizing the risk of falls and injuries.

Common Mistakes to Avoid With Extension Ladder

Not considering the maximum load allowed (SWL) of the ladder:

When utilizing extension ladders, it's crucial to adhere to weight capacity and load limits designated by the ladder's Safe Working Load (SWL). Ignoring these limits can lead to structural failure, posing serious risks to the user's safety. Before using the ladder, always verify that the combined weight of the user and any equipment or materials being carried falls within the specified SWL parameters.

Article: Your Guide to Ladder Safety: Dos and Don'ts You Should Know

Avoid placing excessive weight on one side of the ladder and overreaching:

Maintaining proper balance on the ladder is essential for stability and preventing accidents. Placing too much weight on one side or overreaching can cause the ladder to tilt or topple over, resulting in falls and injuries. Always distribute weight evenly and refrain from reaching out beyond the ladder's sides or top, as this increases the risk of losing balance and falling.

Not maintaining three points of contact when climbing up or down the ladder:

Maintaining three points of contact—such as two hands and one foot or two feet and one hand—while ascending or descending the ladder is a fundamental safety practice. This ensures stability and reduces the likelihood of slipping or falling. Avoid carrying heavy or bulky items that may hinder your ability to maintain three points of contact.

Consider the surface where you're setting up the ladder:

Carefully assess the ground surface before placing the ladder to avoid uneven or contaminated terrain. Uneven ground can cause the ladder to wobble or shift, while contaminated surfaces, such as oily or wet areas, can compromise traction and stability. Always choose a stable, level surface and use stabilizers or footing to enhance stability on uneven terrain.

Failure to maintain the ladder at a 4:1 ratio:

Proper ladder positioning is critical for stability and safety. The 4:1 ratio refers to the angle at which the ladder should be set against the supporting structure. For every four feet of vertical height, the ladder's base should be positioned one foot away from the supporting structure. This optimal angle maximizes stability and minimizes the risk of the ladder sliding or tipping over.

Ensure proper storage and maintenance to prevent damage to the extension ladder components:

Regular inspection, maintenance, and proper storage are essential for preserving the integrity and functionality of extension ladders. Check for signs of wear, corrosion, or damage before each use, and promptly address any issues to prevent further deterioration. Store the ladder in a dry, protected area away from exposure to harsh elements or chemicals that could degrade its materials.

Article: Best Work At Height Solution For Industries: Mega Step Ladder

Utilize ladder safety resources provided by the manufacturer:

Manufacturers often provide comprehensive safety guidelines and resources for their products. Take advantage of these resources, such as instructional manuals, safety videos, or online tutorials, to familiarize yourself with proper ladder usage and safety practices. Stay informed about any updates or recalls issued by the manufacturer to ensure ongoing safety compliance.

Get Your FREE Ladder Safety Checklist

Download

Conclusion:

From selecting the right ladder for the job to avoiding common mistakes, practicing proper ladder usage techniques is crucial for ensuring personal safety and preventing accidents. Make sure to always assess height requirements, material suitability, and weight capacity, and follow safety standards when using extension ladders.

-END-